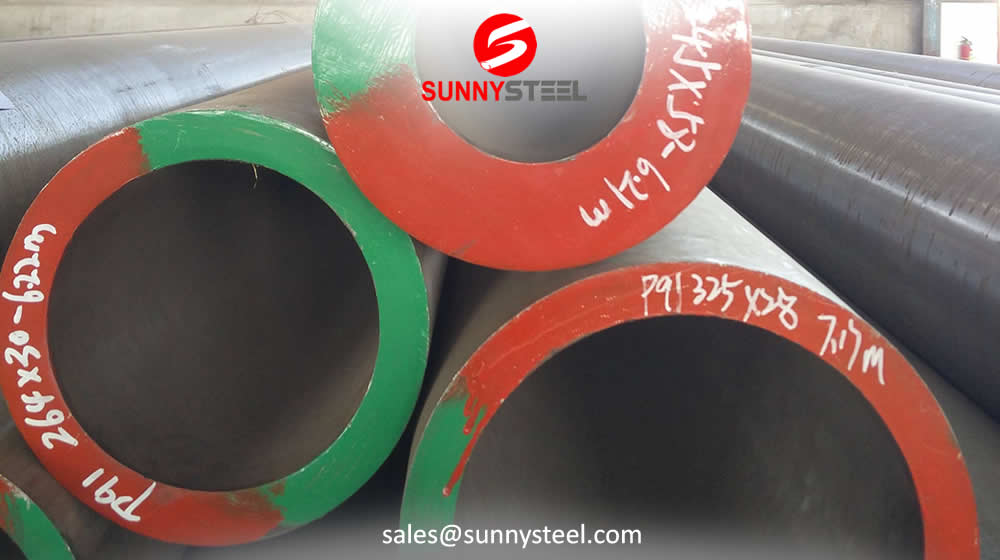

Astm A335 standard specication for seamless ferritic alloy-steel pipe for high-temperature service

ASTM A335 standard is issued under the fixed designation A 335/A 335M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.

This specification covers nominal (average) wall seamless alloy-steel pipe intended for high-temperature service (Mote 1). Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding.

Chemical Compositions(%) of ASTM A335/335M

| Grade | C | Si | Mn | P(≤) | S(≤) | Cr | Mo |

| P11 | 0.05-0.15 | 0.50-1.00 | 0.30-0.60 | 0.025 | 0.025 | 1.00-1.50 | 0.44-0.65 |

| P12 | 0.05-0.15 | ≤0.50 | 0.30-0.61 | 0.025 | 0.025 | 0.80-1.25 | 0.44-0.65 |

| P22 | 0.05-0.15 | ≤0.50 | 0.30-0.60 | 0.025 | 0.025 | 1.90-2.60 | 0.87-1.13 |

| P5 | ≤0.15 | ≤0.50 | 0.30-0.60 | 0.025 | 0.025 | 4.00-6.00 | 0.45-0.65 |

Mechanical Properties of ASTM A335/335M:

| Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) |

| P11 | ≥205 | ≥415 | 20 |

| P12 | ≥220 | ≥415 | 20 |

| P22 | ≥205 | ≥415 | 20 |

| P5 | ≥205 | ≥415 | 20 |

Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

Besides, ASTM A335 covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

*The UNS designation is established in accordance with Practice E527, and SAE J 1086 – Practice for numbering metals and alloys.

*All values are the maximum unless a range is furnished.

*A – 4 times of Carbon≤Titanium≤0.70% or Columbium:8 times of Carbon~10 times of Carbon.

*B – V:0.20-0.30, Cb:0.02-0.08, B: 0.0010-0.006, N:≤0.0015, Al:≤0.030, W:1.45-1.75, Ni:≤0.40, Ti: 0.005-0.060, Ti/N:≥3.5.

*C – Ni:1.00-1.30, Cu:0.50-0.80, Cb:0.015-0.045, V:≤0.02, N:≤0.02, Al:≤0.050.

*D – V:0.18-0.25, N:0.030-0.070, Ni:≤0.40, Al:≤0.02, Cb:0.06-0.10, Ti:≤0.01, Zr:≤0.01.

*E – V:0.15-0.25, N:0.03-0.07, Ni:≤0.40, Al:≤0.02, Cb:0.04-0.09, W:1.5-2.0, B:0.001-0.006, Ti:≤0.01, Zr:≤0.01.

*F – V:0.15-0.30, W:1.30-2.50, Cu:0.30-1.70, Cb:0.04-0.10, B:0.0005-0.005, N:0.040-0.1, Ni:≤0.5, Al:≤0.02, (Ti&Zr):≤0.01.

*G – V:0.18-0.25, Ni:≤0.40, Cb:0.060-0.10, B:0.0003-0.006, N:0.04-0.09, Al:≤0.02, W:0.90-1.10, Ti:≤0.01, Zr:≤0.01.

Specific grades.

Equivalent Alternatives

The alternative to certain grade of ASTM A335 can be found in ASTM A426 and ASTM A369. ASTM A426 is the standard specification for centrifugally cast ferritic alloy steel pipe for high-temperature service. ASTM A369 is the standard specification for carbon and ferritic alloy steel forged or bored pipe for high-temperature service. Both of them specify relatively equivalent grades of Cr-Mo alloy steel pipe. The main difference between ASTM A335, ASTM A426, and ASTM A369 is the manufacture of the pipe: ASTM A335 – hot rolled or cold drawn; ASTM A426 – centrifugal casting; ASTM A369: forging.

Other standards related to the seamless Cr-Mo alloy steel pipe include: ASTM A213 – standard specification for seamless ferritic and austenitic alloy steel boiler, superheater, and heat exchanger tubes; ASTM A199 – standard specification for seamless cold drawn intermediate alloy steel heat exchanger and condenser tubes; ASTM A200 – standard specification for seamless intermediate alloy steel tubes for refinery service.

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.