The crystal structure of sic ceramic wear-resistant elbow is similar to that of diamond tetrahedron, which is a covalent bond, which is a combination of compound, its hardness is high (Morse 9.3), stable performance, physical properties approximate to diamond, it is also called Emery.

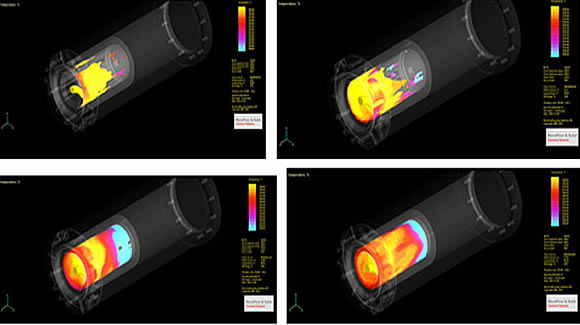

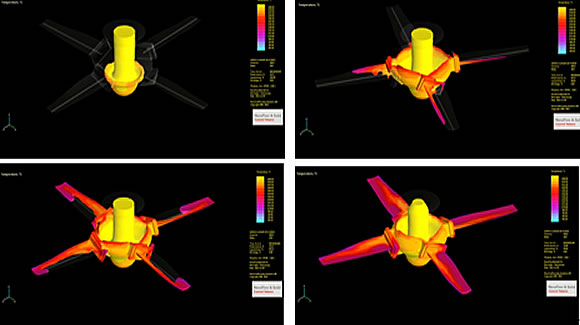

The new silicon carbide alloy ceramic Pipe Cay is based on SIC as the main raw material, SIC ceramics are prepared by mixing, molding, drying and high-temperature sintering by rational particle set, adding silica fume, alumina powder and binder. With high hardness, good wear resistance, thermal stability and resistance to chemical corrosion and other excellent performance, especially with the abrasive attack angle is not sensitive to characteristics.

Product performance

Product Index

Product characteristics

SIC ceramic pipe with SIC as the main raw material, add a variety of chemical wear-resistant raw materials and antioxidants, effectively improve the wear resistance of products to Si0. Micro-powder is a high temperature bonded phase, high temperature sintering of a high-performance sic products. Has the following characteristics:

Product use: Electric power, steel mills, coal chemicals, mines, pipelines.

Exponential parameters:

| Project | Indicators |

| SiC% | 80-90 |

| Apparent porosity % | <20 |

| Volume density g/cm3 | 2.4-2.6 |

| Ambient temperature compressive strength MPa | >85 |

| Thermal conductivity W/m.k | 8 |

| Load Softening temperature ℃ | >1750 |

| Use temperature ℃ | 1500 |

Conveying highly abrasive materials, steel piping systems are under constant attack often over long distances.

Because the outer surface behaves like mild steel, the product can be cut and welded with proper procedure in the field, configured into a variety of fittings, and can accept the standard end options of flanges, weld rings and couplings.

Warranty

We are Quality Department tests and ensures all of our products are 100% inspected unreported. To an offer we customers additional corps of mind, all our products carry a 24-month warranty against defects or faulty workmanship.We fluid-flow products such as pipe and fittings, chokes, orifice plates, etc, carry a warranty against, erosion, defects, and/or faulty workmanship.

The warranty is determined to each creator and the maximum duration maximally in service. Should any of the RS fail within the warranty period, We'll replace or repair the defective product (s) at No. end user. Please contact the Sunny steel for details on the How to obtain a warranty for our products.

Inspections

As part of our quality regimen, 100% of incoming raw materials, semi-finished products, as well as finished products are thoroughly inspected prior to being entered into our inventory. We have established multiple hold points throughout fabrication as well as a comprehensive final inspection for all products.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.