White 92% high ceramic alumina lined wear resistant bend pipe is made through self-propagating high-temperature synthesis (SHS) technique.

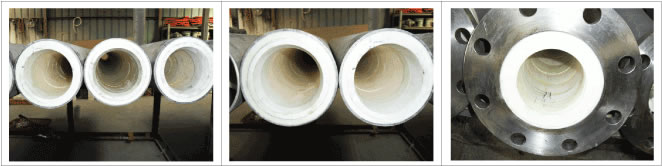

The pipe consists of three layers: smooth ceramic lining (compact corundum), ceramic and metal transition layer and the outer steel pipe.

Wear resistant alumina ceramic rings welded in steel pipes

These Ceramic Tubes are identical to the ones we use in our production, so high quality, consistency, and uniformity are assured.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc.. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Wear-resistant ceramic ring data

High alumina ceramic linings are curved, piping and elbows are reliable, maintain close manufacturing tolerances, and are ready to install, thus facilitating quick replacement and free operation for long lasting trouble. Ceramic liner equipment, including ceramic wire tube, ceramic liner elbow, ceramic liner cone, ceramic turret, ceramic-lined hydrocyclone, ceramic liner, ceramic lined valves to help users obtain the maximum efficiency of the equipment.

Conveying highly abrasive materials, steel piping systems are under constant attack often over long distances.

Because the outer surface behaves like mild steel, the product can be cut and welded with proper procedure in the field, configured into a variety of fittings, and can accept the standard end options of flanges, weld rings and couplings.

Warranty

We are Quality Department tests and ensures all of our products are 100% inspected unreported. To an offer we customers additional corps of mind, all our products carry a 24-month warranty against defects or faulty workmanship.We fluid-flow products such as pipe and fittings, chokes, orifice plates, etc, carry a warranty against, erosion, defects, and/or faulty workmanship.

The warranty is determined to each creator and the maximum duration maximally in service. Should any of the RS fail within the warranty period, We'll replace or repair the defective product (s) at No. end user. Please contact the Sunny steel for details on the How to obtain a warranty for our products.

Inspections

As part of our quality regimen, 100% of incoming raw materials, semi-finished products, as well as finished products are thoroughly inspected prior to being entered into our inventory. We have established multiple hold points throughout fabrication as well as a comprehensive final inspection for all products.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.