A flange is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It also provides easy access for cleaning, inspection, or modification. Flanges are usually welded or screwed.

In many applications, engineers need to find a way to close off a chamber or cylinder in a very secure fashion, usually because the substance inside must differ from the substance outside in composition or pressure.

他们通过日益加快ning two pieces of metal or other material together with a circle of bolts on a lip. This “lip” is a flange.

Plumbing

You can connect two sections of metal piping by soldering or welding them together, but pipes connected in this way are very susceptible to bursting at high pressures. A way of connecting two sections of pipe more securely is by having flanged ends that you can connect with bolts. This way, even if gases or liquids build up to high pressures inside the pipe, it will often hold with no problem.

Mechanics

In order to connect two sections of a large, enclosed area, it is often best to used flanges and bolts. An example of this is the connection between the engine and the transmission in an automobile. In this case, both the engine and the transmission contain a number of moving parts that can easily get damaged if they get dust or other small objects inside of them. By connecting the outer casings of the engine and transmission in this way, engineers protect the inner workings of both.

Electronics

Flanges have a specific purpose in cameras and other electronic devices. Though flanges in such items do not usually have to sustain high pressures, they do have to hold tight so they can keep out harmful particles. These flanges are usually found connecting two different materials, such as the glass of a lens and the rest of the body of the camera.

Applications involving high pressure and the need for a hub that is long and tapered are what weld neck flanges are most often used for. Specifying the schedule of pipe that it will be utilized for is of utmost importance when ordering. This type of flange is excellent for use in environments involving extreme temperature fluctuations and excessive handling and bending.

Uses for Long Weld Neck Flanges

长颈法兰焊接predominan的使用tly on vessels where an extended neck is required. The uses for long weld neck flanges (LWN) are predominantly on vessels where an extended neck is required. This is deemed to be a specialty flange due to the protruding neck or hub, which acts as a boring extension.

锥形颈部有助于降低钢的厚度,然后似乎是管道延伸。钢LWN法兰主要用于化学和石油行业,以及经历高水平的压力和温度波动的商业和住宅建筑物。

There are two types of weld neck flanges, which are standard and long. Standard weld neck flanges are used in butt weld fittings. Long weld neck flanges are used with vessel nozzles and equipment. The flanges are created to match the pipe’s inside diameter or fitting. The reason why it is bored to match is because it reduces the corrosion and turbulence that takes place inside of the pipe.

Spectacle Blinds are generally applied to permanently separating pipesystems, or just to connect with each other. A Spectacle Blind is a steel plate cut into two discs of a certain thickness.

SPECTACLE BLIND INOPEN POSITION  |

SPECTACLE BLIND INCLOSED POSITION  |

Spades and Ring Spacers are basically the same as Spectacle Blinds, except that both are not attached to each other.

Spades and Spacers be applied in systems where maintenance is often not necessary, or in applications with large pipe sizes. Depending on the flange size and the Pressure Class, Spades can weigh hundreds of pounds. To prevent unnecessary weight to a flange connections, usually will be chosen not for a Spectacle Blind, but for 2 separate parts.

RING SPACER

So as for the Spectacle Blind already described, maintenance on a pipesystem can be a reason to temporarily replace a Ring Spacer for a Spade. By loosening of all bolts, and half of the bolts temporarily remove, the Spade or Spacer can be placed. After replacing the gaskets (new gaskets are to recommend), the bolts can be re-assembled and tightened.

A small problem is that we basically can not see, or a Spade or a Spacer mounted between the flanges. Therefore the handles are often specially marked, or both have a different design; a customer often provides its own specification.

What should never lack is, that in the handle, the diameter and the Pressure Class of a Spade or Spacer is engraved; this applies also for the Spectacle Blind.

Surfaces - Dimensions - Material

The sealing surfaces of a Spectacle Blind, Spade or Ring Spacer are usually conducted in accordance with the Face Finish from the flange. The diameter always is slightly larger than the Raised Face of a flange; by a correct assembly, the bolts are just not touched by the Blind or Spacer.

The diameter of them, is depending on the flange size, and the thickness from the Pressure Class of a flange.

Dimensions from Spectacle Blinds, Spades and Ring Spacers, you will find in the main Menu "Flanges"

ASME B16.48 covers pressure-temperature ratings, materials, dimensions, dimensional tolerances, marking, and testing for operating line blanks in sizes NPS 1/2 - NPS 24 for installation between ASME B16.5 flanges in the 150, 300, 600, 900, 1500, and 2500 Pressure Classes.

Spectacle Blinds, Spades and Ring Spacers should be made from a plate or forging specification, approved for use by ASME B31.3, of essentially the same chemical composition as the mating flanges and piping involved.

BLIND FLANGE INCREATE A STOP

Blind flangeare put at the end of pipes or at the junction that would possibly be a future expansion into that direction.

BLIND FLANGE INBLOCK OFF A PIPELINE

A blind flange is a round plate which has all of the relevant blowholes except center hole, and because of this feature the blind flange is usually used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

Often a blind flange is inserted into a pipeline when a repair is required further up the line. This allows the flanges down stream to be disconnected without fear of losing liquid. Many times this type of blockade is used when adding another line onto an existing pipeline or when a new valve is being added. This blockade is also used to shut down a line when it is no longer needed.

Materials for Flanges Based on Applications

Steel pipe flanges have a flat rib, collar or rim that is utilized for guiding or strengthening when attaching two pipes to each other. Materials, sizes and opening dimensions are varying based upon applications that the flanges are designed for and include threaded, socket-wired and slip-on styles.

There are many ways to connect flanges, including threading, welding or bolting. The threaded flange is best for low pressure or smaller pipelines because it can maintain its seal. When your pipeline is larger or high pressure, then the welded flange is preferable. A boiler room is one place where welded blind flanges might be used, due to the high pressure involved.

A flange is a external rib at the end of pipes, valves and other flow devices to assemble them.

Dimensions of the flanges are up to specific Standards : DIN, ANSI, AS, BS, JIS

A flanged connection requires two flanges (the "main" and the "companion"), a set of bolts and nuts (whose number depends on the flange diameter and class) and two sealing gaskets. Flanged connections have to be executed and supervised by trained personnel, as the quality of the joint has a critical impact on the performance of the piping system / pipeline (the standard TSE - TS EN 1591 Part 1-4, "Flanges and their joints", defines a number of requirements for the execution of proper flanged connections). Whereas all elements of the joint are critical, experience shows most leaks are originated by the improper installation of the sealing elements, i.e. the gaskets.

The typical pipe to flange connections are welded or threaded. Welded flanges are used for pipelines and piping systems with high pressures and temperatures, and with diameters above 2 inches.

螺纹连接替代地用于较小直径的安装,而不经受严苛的机械力,例如膨胀,振动,收缩,振荡(将破裂螺纹接头)的力。在所有这些关键情况下,建议使用对接焊接连接。

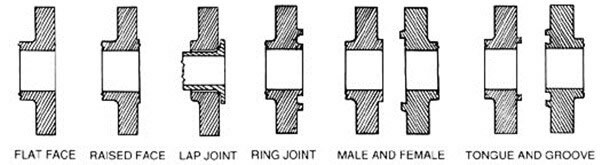

Type of face flanges

There are different flanges profiles.

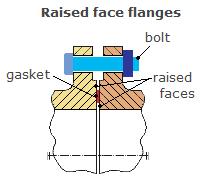

Raised Face Flange RFRaised Face Flanges (RF):

RF flanges seal with a flat gasket designed for installation between the raised faces of two mating flanges (both with raised faces). The raised faces have a prescribed texture to increase their gripping and retaining force on this flat gasket. Some users of raised face flanges specify the use of spiral wound gaskets.

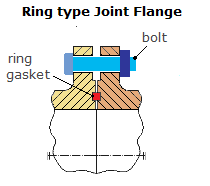

Ring Type Joint Face RTJRing Type Joint Flanges (RTJ) or Ring Joint Facing Flanges (R-JF):

环连接面法兰槽切成脸上制作h accept steel Ring Gaskets. RTJ flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or "Coining") the gasket to make Intimate Contact inside the grooves, creating a metal to metal seal.

RTJ法兰可以具有凸起的面部,该凸起面具有机械加入其中的环槽。这张凸起的面不作为密封装置的任何部分。对于用Bx环垫圈密封的RTJ法兰,连接和拧紧法兰的凸起面可能彼此接触。在这种情况下,压缩垫圈不会承受超过螺栓张力的额外负载,振动和运动不能进一步压碎垫圈并减少连接张力。

Connection types of flanges can generally be divided into five kinds: flat welding, butt welding, socket welding, loose and threaded.

Flange easy to use, able to withstand greater pressure. Below is the detailed description of first four kinds:

As we know, the steel piping system could move and shake when the liquid flowing through the pipe, especially when the piping system is turning in some places, the liquid will push the turning in the direction of liquids flowing. Another application of the anchor flange, there may bring expansion movements when temperature is changing in the piping system.

Anchor flange are corrosion resistant and have a wide variety of uses. We carry a variety of threaded flanges, weld neck flanges and slip- on flanges and, of course, we can can custom build steel flanges to your specifications.

Lap Joint Flanges (LJ Flanges) are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges.

Requirements are valid for normal case, in special case you have to contact the technical department.

Below you will find a short description and definition of each type, completed with an detailed image.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.