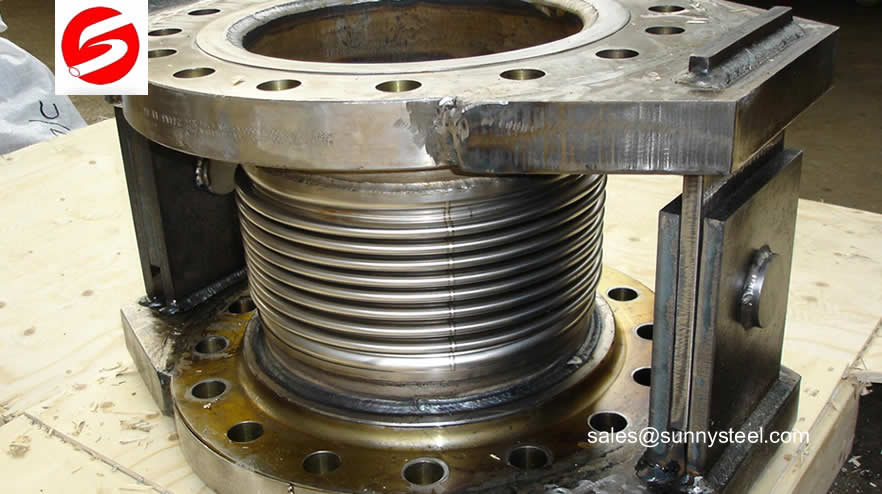

Bellows Expansion Joints are great for accommodating axial, lateral and angular movements for a wide array of piping applications.

一些应用程序可能包含高流动速度, which can induce severe vibration and lead to premature failure to the bellows element. The way to address this is to utilize a bellows expansion joint containing an internal sleeve, also known as a flow liner.

膨胀接头的波纹管由相对薄的材料制成,以提供吸收特定运动所需的灵活性。如果单位不正确地处理和/或安装,则可以缩短扩展的寿命。这可以通过在安装期间或因素中施加的压力来源对波纹管的直接物理损坏。因此,必须遵循一些基本说明,安全且正确地安装扩展关节。

There are several other things to consider when choosing whether or not to use a flow liner. Due to lateral movements, the gap between the bellows and the internal sleeve must be designed appropriately in order to prevent contact or binding against the inside diameter of the pipe or fitting. Also, making sure the inside diameter of the internal sleeve does not create back pressure or restrict the flow of media is extremely important, and usually can be avoided by utilizing an oversize bellows.

Stainless steel bellows, as a flexible pressure-resistant pipe fittings, are installed in the liquid transportation system to compensate for the mutual displacement of the connecting ends of pipes or machines and equipment, absorb vibration energy, and can play the role of vibration reduction and silencing. They have many characteristics, such as good flexibility, light weight, corrosion resistance, fatigue resistance, high and low temperature resistance.

| DN | Quantity of ripple | 压力水平 | 合成管的有效面积 | Maximum external diameter(mm) | ||||

|---|---|---|---|---|---|---|---|---|

| 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | ||||

| 轴向补偿长度mm /韧性n / mm | ||||||||

| 32 | 8 | 25/21 | 22/26 | 20/26 | 18/63 | 16 | 225. | |

| 32 | 16 | 50/11 | 46/14 | 41/14 | 36/32 | 16 | 225. | |

| 40 | 8 | 25/25 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 |

| 40 | 16 | 50/14 | 46/22 | 41/22 | 36/45 | 31/47 | 23 | 244 |

| 50 | 8 | 25/30 | 22/51 | 20/70 | 18/70 | 15/106 | 37 | 259 |

| 50 | 16 | 50/16 | 46/26 | 41/35. | 36/35 | 31/55 | 37 | 259 |

| 65 | 8 | 33/28 | 30/35 | 26/44 | 22/55 | 15/138 | 55 | 270 |

| 65 | 12 | 42/16 | 38/22 | 38/32 | 34/40 | 31/70 | 55 | 270 |

| 80 | 8 | 40/20 | 36/26. | 34/33 | 28/41 | 19/68 | 81 | 284 |

| 80 | 10 | 53/14 | 49/17 | 49/21 | 43/26 | 29/50 | 81 | 284 |

| 100. | 6 | 45/47 | 45/60. | 40/75 | 35/93 | 25/54 | 121 | 304. |

| 100. | 10 | 76/26 | 74/32 | 64/40 | 57/50 | 38/33 | 121 | 304. |

| 125 | 5 | 48/38 | 42/47 | 38/59 | 34/74 | 29/117 | 180 | 334. |

所有应用的金属波纹管和扩展波纹管

我们的扩展联合结构根据您的需求提供轴向,横向或角平面的灵活性。它们对集合参数内的张力和压缩具有高度耐张力,可提供对产品的寿命安全,高效,可靠的操作。

Stainless steel bellows expansion joint is the compensating elements installed in pipelines, machines and containers, we often call it compensator.

Stainless steel bellows expansion joint mainly has three basic movement types: axial movement, lateral movement and angular movement. What’s the function of stainless steel bellows expansion joint? Generally speaking the functions are absorbing vibration, compensating movement and absorbing noise. Please check below detailed information.

吸收管道振动

一方面,不锈钢波纹管膨胀接头可以增强疲劳破裂容量,另一方面,它具有减少管道噪音的功能。

Compensating piping movement

Take rubber hose as comparison, rubber hose has good flexibility and strong anti-fatigue ability, but it is inferior in temperature resistance, pressure bearing, aging resistance than stainless steel bellows expansion joint, it always needs to be changed after using a few months. While metal bellows owns comprehensive performances of out-standing corrosion resistance, temperature resistance, pressure resistance, fatigue resistance, in some complex environment, stainless steel bellows expansion joint is the most ideal element to compensate piping movements.

Piping installation stress

典型的安装问题总是在一些复杂的管道系统中看到的,问题总是由于空间和位置的限制而引起的。根据不同的管道直径和工作环境,冷矫直值不同于几毫米至数十毫米,甚至数百毫米。实践证明,较大的冷矫直值,内部应力越高,内部应力是管道系统的隐性危险。由于不锈钢波纹管膨胀节能够自由地弯曲并产生最大限度地减少额定弯曲半径的内部应力,因此,安装是非常方便的,这就是为什么不锈钢波纹管膨胀接头是一些管道系统的必要管道配件的原因。

金属波纹管是当压力施加到容器的外部或在真空下延伸时,可以压缩的弹性容器。当压力或真空被释放时,波纹管将返回其原始形状(如果材料尚未压力超过其屈服强度)。

Expansion joints and metal bellows are vital components in a huge range of industrial settings. They play a vital role in equipment which needs to withstand high pressures, whether that is from gases or liquids. The units are designed to safely and reliably expand under pressure, and take prescribed temperatures in their stride. They can be formed from common metals such as stainless steel in various grades, and more exotic alloys such as Inconel can be used as per your requirements.

Metal Bellow Types

There are two main types of metal bellows – formed and welded. Formed bellows are produced by reworking tubes, normally produced by deep drawing, with a variety of processes, including cold forming (rolling), electroforming and hydroforming. They are also called convoluted bellows or sylphons.

Welded bellows (also called edge-welded, or diaphragm bellows) are manufactured by welding a number of individually formed diaphragms to each other. The comparison between the two bellows types generally centers around cost and performance. Hydroformed bellows generally have a high tooling cost, but, when mass-produced, may have a lower piece price. However, hydroformed bellows have lower performance characteristics due to relatively thick walls and high stiffness. Welded metal bellows are produced with a lower initial tooling cost and maintain higher performance characteristics. The drawback of welded bellows is the reduced metal strength at weld joints, caused by the high temperature of welding. Electroformed bellows can be produced with modest tooling costs and with thin walls (25 micrometres or less), providing them with high sensitivity and precision in many exacting applications.

Another area of comparison is in metals of construction. Hydroformed and rolled bellows are limited to metals with high plastic elongation characteristics, whereas welded bellows may be fabricated from a wider variety of standard and exotic alloys, such as stainless steel and titanium, as well as other high-strength, corrosion-resistant materials. Electroformed bellows can be produced of nickel, its high-strength alloys, and copper.

Metal bellow Applications

波纹管,焊接或复杂的(形成)用于大量的工业应用。您会发现一些:

Load cells-A load cell deforms if a certain load in the form of a pressure or a strain is imposed on it. This deformation is then detected by a strain gauge through which a low voltage direct current is flowing. The change in voltage is detected and made visible on a control panel. A bellows is mounted over the gauge to protect it from outside influences.

Vacuum interrupters-For the switching of very high voltages in transformer stations sparks should be avoided. To prevent any danger that the surrounding atmosphere will explode, oxygen has to be removed in the area where the sparks occur. This can be done by sealing the spark area completely. Bellows are used to seal such confined volumes and the inside of the bellows is evacuated or filled with an inert gas.

Mechanical Seals-These are mostly used to close the inside of a pump from the outside world to prevent leakage. For that purpose, a mechanical seal is mounted on the pump shaft. As the pump shaft is turning, there has to be a sealing element consisting of a stationary and a rotating ring. To enforce sufficient pressure on the two rings one is fitted with a spring. This spring can also have the form of a diaphragm (welded) bellow.

压力表 - 如果必须测量腐蚀性流体或气体的压力,则必须从流动中分离规格。对于关键应用,使用隔膜密封代替压力表中的BOURDON管。这提供了更大的安全性,即攻击性媒体不会泄漏。隔膜是一种自包含的传感器,将位移传递到测量装置。

Sensors- In this application diaphragm or convoluted bellows are completely sealed and filled with a certain gas. Two electrical poles are penetrating the inside of the bellows. By varying the current of those two poles the temperature inside the bellows can be regulated. The expansion or contraction of the bellows is used as an actuator to control a certain movement.

Valve Sealing- A bellows is used between the housing and the rising stem to seal the inside completely from the outside world. In Europe this is of particular importance as regulations such as TA Luft prohibit any leakage.

Couplings for stepper motors and servomotors- The flexible part, capable of compensating for misalignment is made by a bellows. It ensures that there is no angular positioning difference between the two coupling halves. This is essential if the positioning accuracy should be extremely precise.

Exhaust Bellows- Running engines cause self vibration. To compensate for those movements and temperature differences resulting in thermal expansion, bellows are used to connect the exhaust gas pipes to the funnel.

Piping expansion joint-In this application, bellows are formed in series to absorb thermal movement and vibration in piping systems that transport high temperature media such as exhaust gases or steam.

金属波纹管也用于其他产品和市场段,包括植入药物泵等医疗应用,以及工业执行器,适用于航空航天应用,如高度传感器和流体管理装置(蓄能器,浪涌避雷器,体积补偿器和流体存储器)。在太空应用中也发现了金属波纹管,提供带有饮用水的水库以及蓄水器来收集废水。

Metal bellow Applications

波纹管,焊接或复杂的(形成)用于大量的工业应用。您会发现一些:

Load cells-A load cell deforms if a certain load in the form of a pressure or a strain is imposed on it. This deformation is then detected by a strain gauge through which a low voltage direct current is flowing. The change in voltage is detected and made visible on a control panel. A bellows is mounted over the gauge to protect it from outside influences.

Vacuum interrupters-For the switching of very high voltages in transformer stations sparks should be avoided. To prevent any danger that the surrounding atmosphere will explode, oxygen has to be removed in the area where the sparks occur. This can be done by sealing the spark area completely. Bellows are used to seal such confined volumes and the inside of the bellows is evacuated or filled with an inert gas.

Mechanical Seals-These are mostly used to close the inside of a pump from the outside world to prevent leakage. For that purpose, a mechanical seal is mounted on the pump shaft. As the pump shaft is turning, there has to be a sealing element consisting of a stationary and a rotating ring. To enforce sufficient pressure on the two rings one is fitted with a spring. This spring can also have the form of a diaphragm (welded) bellow.

压力表 - 如果必须测量腐蚀性流体或气体的压力,则必须从流动中分离规格。对于关键应用,使用隔膜密封代替压力表中的BOURDON管。这提供了更大的安全性,即攻击性媒体不会泄漏。隔膜是一种自包含的传感器,将位移传递到测量装置。

Sensors- In this application diaphragm or convoluted bellows are completely sealed and filled with a certain gas. Two electrical poles are penetrating the inside of the bellows. By varying the current of those two poles the temperature inside the bellows can be regulated. The expansion or contraction of the bellows is used as an actuator to control a certain movement.

Valve Sealing- A bellows is used between the housing and the rising stem to seal the inside completely from the outside world. In Europe this is of particular importance as regulations such as TA Luft prohibit any leakage.

Couplings for stepper motors and servomotors- The flexible part, capable of compensating for misalignment is made by a bellows. It ensures that there is no angular positioning difference between the two coupling halves. This is essential if the positioning accuracy should be extremely precise.

Exhaust Bellows- Running engines cause self vibration. To compensate for those movements and temperature differences resulting in thermal expansion, bellows are used to connect the exhaust gas pipes to the funnel.

Piping expansion joint-In this application, bellows are formed in series to absorb thermal movement and vibration in piping systems that transport high temperature media such as exhaust gases or steam.

金属波纹管也用于其他产品和市场段,包括植入药物泵等医疗应用,以及工业执行器,适用于航空航天应用,如高度传感器和流体管理装置(蓄能器,浪涌避雷器,体积补偿器和流体存储器)。在太空应用中也发现了金属波纹管,提供带有饮用水的水库以及蓄水器来收集废水。

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.