Stainless steel matal hose is a kind of flexible hose with high quality in modern industrial pipeline.

The inner tube of metal bellows hose is spiral or annular thin-wall stainless steel bellows, the outer braid mesh of bellow pipe(corrugated pipe) is made of stainless steel wire and steel belt according to certain parameters,the joints or flanges on both ends of the hose are matched to the joint or flange of the customer's pipe.

| Nominal diameter DN | Inner |

Outer diameter | Minimum bending | Working pressure | |||

|---|---|---|---|---|---|---|---|

| Bellows | 编织网 | Static | Dynamic | Single braid mesh | Double braid mesh | ||

| 8 | 8.8 | 13.2 | 14.4 | 50 | 110 | 15 | 20 |

| 10 | 11.7 | 16.5 | 17.7 | 65 | 145 | 185 | 20 |

| 15 | 13.5 | 19.5 | 21.1 | 80 | 180 | 18 | 20 |

| 20 | 20.0 | 27 | 28.6 | 120 | 270 | 10 | 15 |

| 25 | 27.0 | 34.5 | 36.1 | 160 | 360 | 6.3 | 10 |

| 32 | 32.0 | 40 | 41.6 | 175 | 400 | 4.0 | 6.3 |

| 40 | 39.6 | 52 | 53.6 | 225 | 510 | 4.0 | 6.3 |

| 50 | 49.7 | 62 | 63.6 | 280 | 640 | 3.0 | 5.0 |

| 65 | 61.2 | 80.2 | 81.8 | 410 | 915 | 3.0 | 5.0 |

| 80 | 79.0 | 96.3 | 97.9 | 486 | 1030 | 3.0 | 5.0 |

| 100 | 101.2 | 119.6 | 121.2 | 610 | 1340 | 2.5 | 4.0 |

| 125 | 124.1 | 145.3 | 146.9 | 700 | 1540 | 2.5 | 4.0 |

| 150 | 149.4 | 180.8 | 182.4 | 810 | 1780 | 2.5 | 4.0 |

SS304

SUS 304 Austenite stainless steel is usually referred to as the Japanese name for SS304 or AISI 304 stainless steel.304 stainless steel is a common material of stainless steel, the density of 7.93 g/cm3 and resistance to high temperature 800 ° C.It has good processing performance and high toughness.They are widely used in medical industry and furniture decoration industry and food industry.

Flexible metal hose made with ss304 has good comprehensive performance of corrosion resistance and formability.Stainless steel 304 flexible metal hose is durable in use , good and inexpensive, will bring the best result of use and good economic benefits to you.

SS321

ss321 is a stabilized stainless steel which offers as its main advantage an excellent resistance to intergranular corrosion following exposure to temperatures in the chromium carbide precipitation range from 800 to 1500° F (427 to 816° C).

ss321 also advantageous for high temperature service because of its good mechanical properties. sss321 offers higher creep and stress rupture properties than ss304.Therefore,if your tube needs to work under high temperature conditions, please select the flexible metal hose made by ss321.

SS316L

Type 316L stainless steel is an extra-low carbon version of the 316 steel alloy. SS316L has good corrosion resistance and is resistant to marine and aggressive industrial atmospheres.The lower carbon content in 316L minimizes deleterious

In order to understand flexible metal hose assemblies and how they serve various applications it’s best to review their anatomy. In its simplest form, a metal hose is made of four basic components:

Separately, these parts are really quite simple. However, they can be customized to form a variety of configurations, enabling flexible metal hoses to be an optimal solution in a number of industries. Let’s examine each of these components individually and discuss how they all work together to create value.

The corrugated tubing is the core component of a flexible metal hose. Not only does it comprise the bulk of an assembly, but it also plays a part in key value-added attributes of the assembly, such as corrosion resistance, pressure rating, and flexibility.

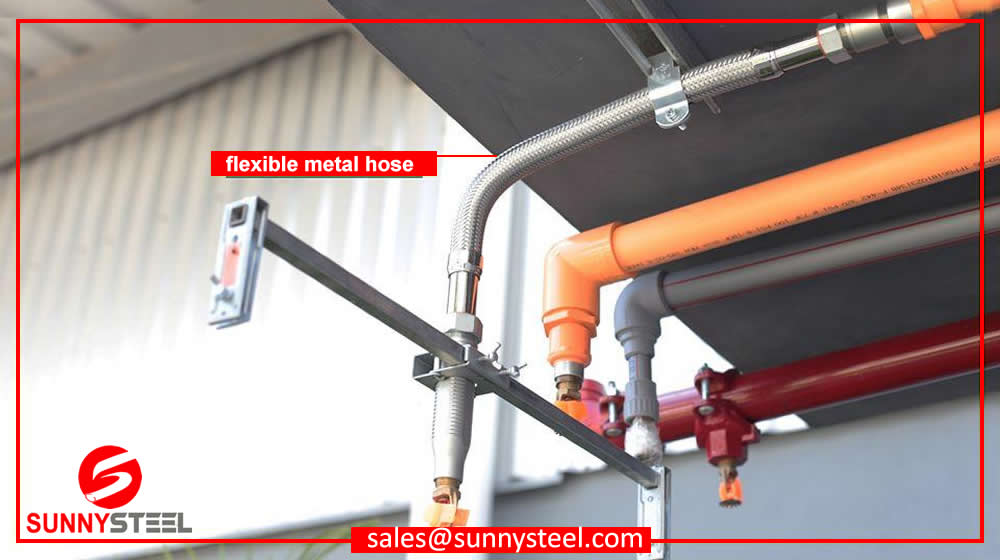

Flexible metal hose also called corrugated metal hose is especially designed to achieve several objectives in pipe work design. With reliable, quick and easy connection with time-saving, pressure and temperature-resistant,absorbing vibrations and expansion etc.

Stainless steel corrugated hose is a general purpose industrial hose and is available in different grades of stainless steel including 304, 316L, 321,etc.There are many different kinds of metal hose fittings,such as gas hose fitting,quick camlock,flange,NPT fittings,BSP fittings,etc.The flexible metal hose with fittings is more conducive to function in the piping system.

A high-coverage braid package can help add to a hose assembly’s cycle life.

The applications that we support range from metal hose requirements for furnace cooling applications, oxygen services, HVAC offsets, hot asphalt jumper hoses, flanged assemblies for flex connectors, chemical processing, petroleum based applications, natural gas, vibration absorption hoses, earthquake hoses and much more. We test our hose assemblies with helium under water, and hydrostatic testing to customer requirements.

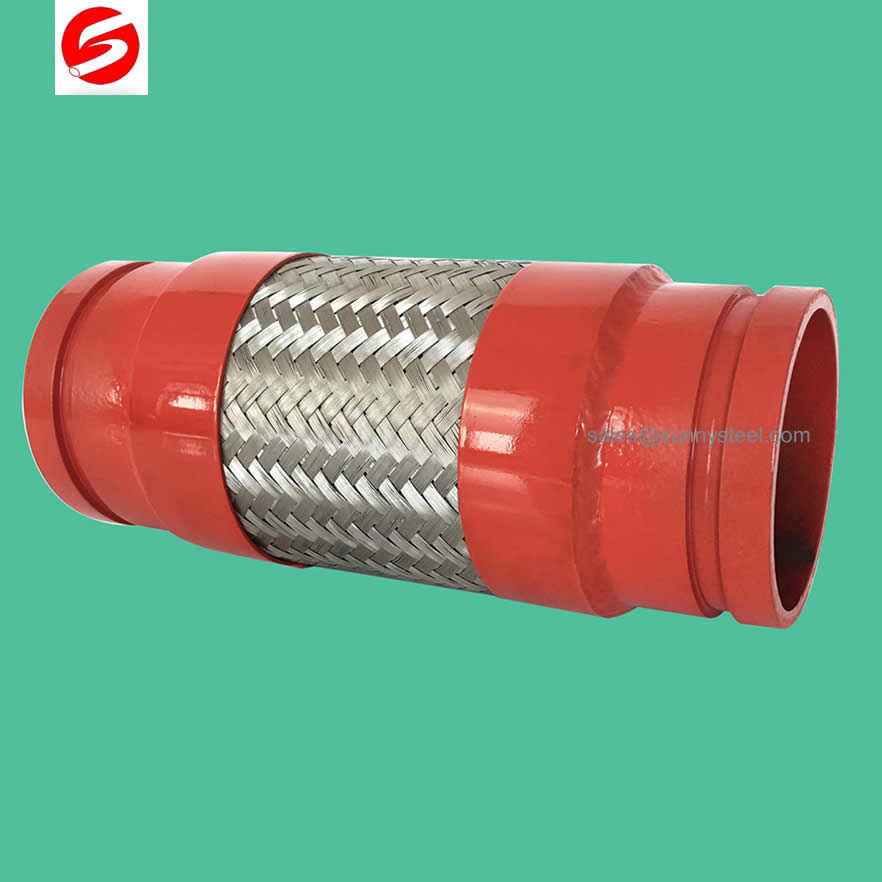

Flange connection type, produced according to customer requirements

High Quality 304 316 Corrugated Stainless Steel Flexible Metal Hose with Flange

Flange connection type, produced according to customer requirements

It is made of flexible bellows tube, nets and joint.

Flange connection metal hose’s application range covers aviation, aerospace, petroleum, chemical engineering, metallurgy, electric power, papermaking, wood, spinning, construction, medicine, food, tobacco, transportation industries, as well as in wiring protection of railway, engine, air-condition, all kinds of machinery, automatic control equipment, electricity generation, power transmission and distribution system, communication system, ship, building, workshop and exposed part in outside.

Widely used in aviation, aerospace, petroleum, chemical, metallurgy, power, paper, wood, textile, construction, pharmaceutical, food, tobacco, transportation and other industries.

The applications that we support range from metal hose requirements for furnace cooling applications, oxygen services, HVAC offsets, hot asphalt jumper hoses, flanged assemblies for flex connectors, chemical processing, petroleum based applications, natural gas, vibration absorption hoses, earthquake hoses and much more.

For wire and cable protection tube and civilian shower hose.

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.