An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 90° or 45° angle, though 22.5° elbows are also made.

The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

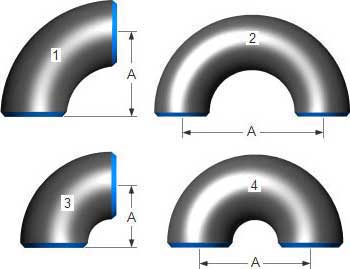

By default, there are 5 opportunities, the 45°, 90° and 180° elbows, all three in the "long radius" version, and in addition the 90° and 180° elbows both in the "short radius" version.

Long Radius (LR) Elbows – radius is 1.5 times the pipe diameter

Long Radius (LR) Elbows – radius is 1.5 times the pipe diameter

Short Radius (SR) Elbows – radius is 1.0 times the pipe diameter

Short Radius (SR) Elbows – radius is 1.0 times the pipe diameter

Elbows are split into two groups which define the distance over which they change direction; the center line of one end to the opposite face. This is known as the "center to face" distance and is equivalent to the radius through which the elbow is bent.

Here below, for example, you will find the center to face distance of NPS 2 elbows (the A distance on the image)

The center to face distance for a "long" radius elbow, abbreviated LR always is "1½ x Nominal Pipe Size (NPS) (1½D)", while the center to face distance for a "short" radius elbow, abbreviated SR even is to nominal pipe size.

3D elbows as an example, are calculated with:

3(D) x 2(NPS) x 25.4

| Nominal pipe size | Outside Diameter at Bevel |

Center to End | Center to Center | Back to Faces | ||||||

| 45° Elbows | 90°Elbows | 180°Return | ||||||||

|

H |

F |

P |

K |

|||||||

DN |

INCH |

Series A | Series B | LR | LR | SR | LR |

SR |

LR |

SR |

|

15 |

1/2 |

21.3 |

18 |

16 |

38 |

- |

76 |

- |

48 |

- |

|

20 |

3/4 |

26.9 |

25 |

16 |

38 |

- |

76 |

- |

51 |

- |

|

25 |

1 |

33.7 |

32 |

16 |

38 |

25 |

76 |

51 |

56 |

41 |

|

32 |

11/4 |

42.4 |

38 |

20 |

48 |

32 |

95 |

64 |

70 |

52 |

|

40 |

11/2 |

48.3 |

45 |

24 |

57 |

38 |

114 |

76 |

83 |

62 |

|

50 |

2 |

60.3 |

57 |

32 |

76 |

51 |

152 |

102 |

106 |

81 |

|

65 |

21/2 |

76.1(73) |

76 |

40 |

95 |

64 |

191 |

127 |

132 |

100 |

|

80 |

3 |

88.9 |

89 |

47 |

114 |

76 |

229 |

152 |

159 |

121 |

|

90 |

31/2 |

101.6 |

- |

55 |

133 |

89 |

267 |

178 |

184 |

140 |

|

100 |

4 |

114.3 |

108 |

63 |

152 |

102 |

305 |

203 |

210 |

159 |

|

125 |

5 |

139.7 |

133 |

79 |

190 |

127 |

381 |

254 |

262 |

197 |

|

150 |

6 |

168.3 |

159 |

95 |

229 |

152 |

457 |

305 |

313 |

237 |

|

200 |

8 |

219.1 |

219 |

126 |

305 |

203 |

610 |

406 |

414 |

313 |

|

250 |

10 |

273.0 |

273 |

158 |

381 |

254 |

762 |

508 |

518 |

391 |

|

300 |

12 |

323.9 |

325 |

189 |

457 |

305 |

914 |

610 |

619 |

467 |

|

350 |

14 |

355.6 |

377 |

221 |

533 |

356 |

1067 |

711 |

711 |

533 |

|

400 |

16 |

406.4 |

426 |

253 |

610 |

406 |

1219 |

813 |

813 |

610 |

|

450 |

18 |

457.2 |

478 |

284 |

686 |

457 |

1372 |

914 |

914 |

686 |

|

500 |

20 |

508.0 |

529 |

316 |

762 |

508 |

1524 |

1016 |

1016 |

762 |

|

550 |

22 |

559 |

- |

347 |

838 |

559 |

||||

|

600 |

24 |

610 |

630 |

379 |

914 |

610 |

||||

|

650 |

26 |

660 |

- |

410 |

991 |

660 |

||||

|

700 |

28 |

711 |

720 |

442 |

1067 |

711 |

||||

|

750 |

30 |

762 |

- |

473 |

1143 |

762 |

||||

|

800 |

32 |

813 |

820 |

505 |

1219 |

813 |

||||

|

850 |

34 |

864 |

- |

537 |

1295 |

864 |

||||

|

900 |

36 |

914 |

920 |

568 |

1372 |

914 |

||||

|

950 |

38 |

965 |

- |

600 |

1448 |

965 |

||||

|

1000 |

40 |

1016 |

1020 |

631 |

1524 |

1016 |

||||

|

1050 |

42 |

1067 |

- |

663 |

1600 |

1067 |

||||

|

1100 |

44 |

1118 |

1120 |

694 |

1676 |

1118 |

||||

|

1150 |

46 |

1168 |

- |

726 |

1753 |

1168 |

||||

|

1200 |

48 |

1220 |

1220 |

758 |

1829 |

1219 |

||||

Weight of elbows

| NPS inches |

ELBOWS LR 90° |

ELBOWS SR 90° |

||||||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

Angularity Tolerances

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

Key Specifications/Special Features and Materials:

the material is selected accoding to the application use such as high temperature use,sanitary fitting,regular industrial use etc.

Application of pipe elbows: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc.

Wall Thickness of Elbows

The weakest point on an elbow is the inside radius. ASME B16.9 only standardizes the center to face dimensions and some "squareness" dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of an elbow. The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting.

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.