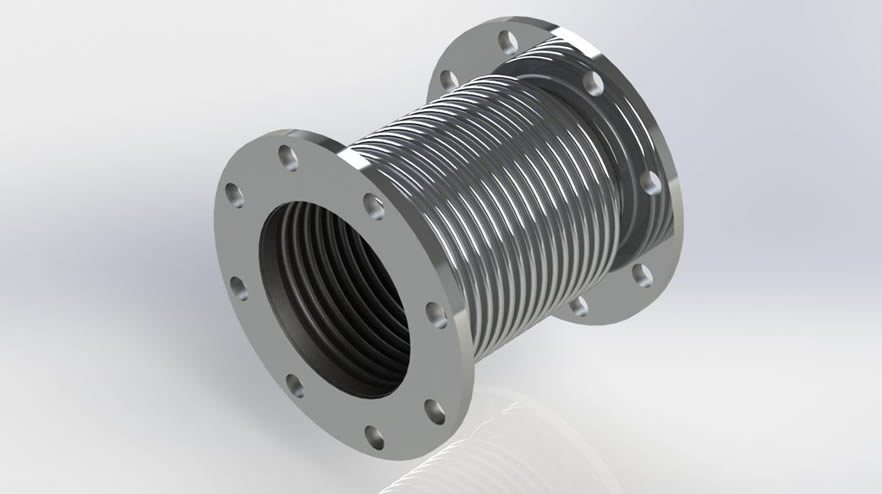

Pipe expansion joints are also known as compensators, as they 'compensate' for the thermal movement.

管膨胀接头是传送蒸汽或废气等高温商品的系统中所必需的,或吸收运动和振动。用于管道系统的典型膨胀接头是波纹管,可以由金属(最常见的不锈钢),塑料(如PTFE)或诸如橡胶的弹性体制成。

波纹管由一系列或多个卷曲构成,卷积的形状设计用于承受管的内部压力,而是足够灵活地接受轴向,横向和/或角度偏转。膨胀接头还专为其他标准设计,例如降噪,防振,地震运动和建筑沉降。

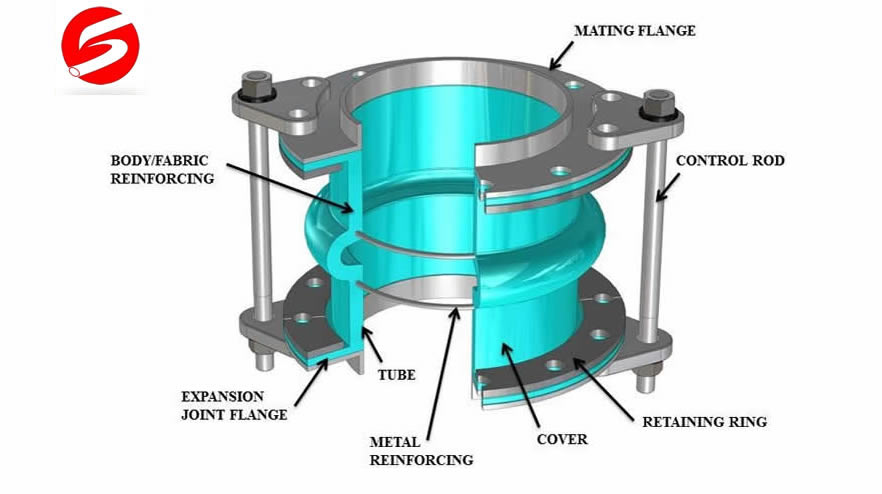

Tube– A protective, leak proof lining made of synthetic or natural rubber. The tubes primary function is to eliminate the possibility of materials being handled penetrating the carcass.

Carcass – The carcass or body of the expansion joint consists of fabric, and when necessary metal.

Cover– The exterior surface of the joint.

织物加固- 胎体织物加强件是管和盖子之间的柔性和支撑构件。

Metal Reinforcement– Wire or solid steel rings imbedded in the carcass, often used for strengthening.

Retaining Ring– Used to compress the expansion joint flange to the mating flange to create a seal. Also called clamp bars or backing bars. Applies to most all expansion joints.

Mating Flange– Used to connect the pipe joint to the pipe in which it is being installed.

Control Rod- 用于限制操作期间的轴向运动,并防止接头超出其运动能力。杆连接配合法兰和膨胀接头。通常用于管道接头,但在需要时可以安装在大多数接头上。

Expansion joints are an assembly designed to safely absorb sound, expansion, con traction and vibration to ensure expansion jointsthat the application stays in fully working order.

这些设备用于管道工作,其中运动,热膨胀等可能导致问题。管膨胀接头由一个或多个卷曲构成,该卷曲设计用于移动或扩展以缓解来自实心管的应力。应用程序内的移动或扩展量将确定所需卷积的数量和形状。膨胀接头可以从一系列不同的材料,从不锈钢和PTFE制成,橡胶。

Pipe expansion joints are also designed for other criteria, such as noise absorption, anti vibration, earthquake movement and building settlement. Metal expansion joints have to be designed according to rules. Pipe expansion joints are used in a number of industries, including; oil, petrochemical and paper industries.

Pipe expansion joints are often manufactured to withstand temperatures from minus 300°F, up to 4000°F, as well as being able to resist at full vacuum or 2000 psig. Expansion joints can be manufactured from a range of different materials aforementioned. Before the introduction of pipe expansion joints, engineers were battling with the task of combating problems regarding thermal expansion, corrosion and abrasive factors that took effect on the functionality of various applications. Fabric joints can be used in a number of applications for turbines and pipelines, which can defend against resistance, heat and a range of other environmental factors.

Pipe expansion joints are crucial components in the pipe technology sector, which serve a huge number of industries. They are used to counterbalance length changes that generally occur in pipelines from temperature changes and can also absorb vibrations. It is a cost effective solution to increase the life span, reliability and costs of many applications through equipment and process management.

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.