该厂采用连续轴扭曲J-C-O(j-ing,c-ing和O-ing)process with characteristics of high forming accuracy and efficiency as well as balanced distribution of forming stress.

+ JCOE pipesJCOE manufacturing technology is developed in the 1990s as a pipe forming process, the process of molding process is the first major steel mill edge (or planing) after pre-bending by longitudinal side, and then type → J-→ C O-order molding, stamping each step are the basic principles of three-point bending.

Because it is a progressive multi-pass pressing, it must address the following questions: how to determine the die shape, the upper die and lower die stroke distance, and how much press pass in order to ensure the most appropriate bend radius and the best opening round hair tube. But these issues with the steel plate, steel plants of different mechanical properties of concrete, pipe size (diameter and wall thickness), which in turn is very complex. Currently mainly by "trial and error", that is, whenever replacement or new steel specifications, we take a certain number of sample pressure test, worked out the right amount of punch. Trial and error method is more reliable, but the efficiency is relatively low.

As more process parameters, only through trial and error method is quite cumbersome. In order to obtain a mature technology, and even a few months of trial and error process. And trial and error process is often a fixed shape and spacing of the die, only to explore the punch stroke, so the results obtained may not be optimal, there is no full unit capacity. System so it is necessary to study the factors affecting the shape, or even to establish a theoretical formula, developed with the experience of trial and error molding process, eliminating the need or less need to test, trial costs and reduce time and increase productivity.

该厂采用连续轴扭曲J-C-O(j-ing,c-ing和O-ing)process with characteristics of high forming accuracy and efficiency as well as balanced distribution of forming stress.

The mill has the advantages of wide specifications and can produce pipes in any size within its production range.

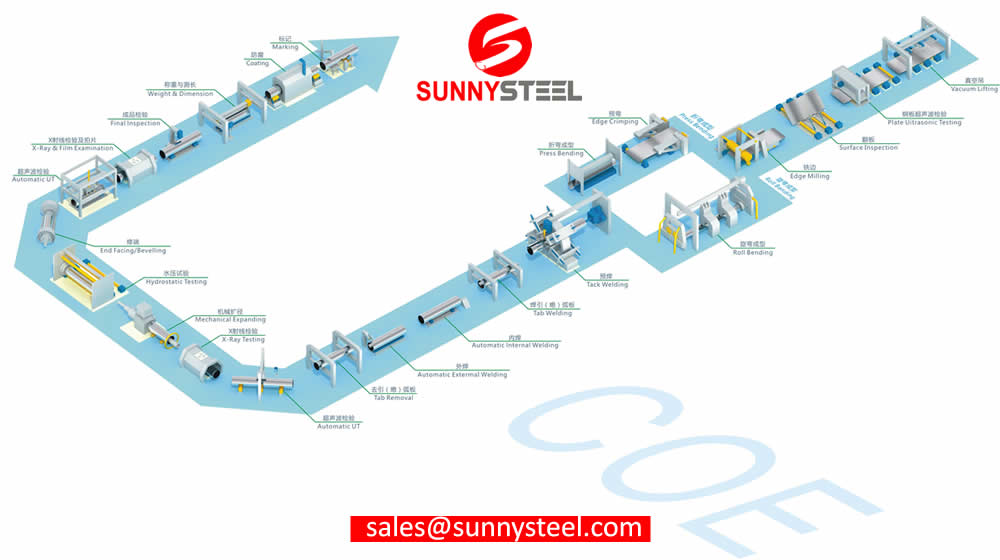

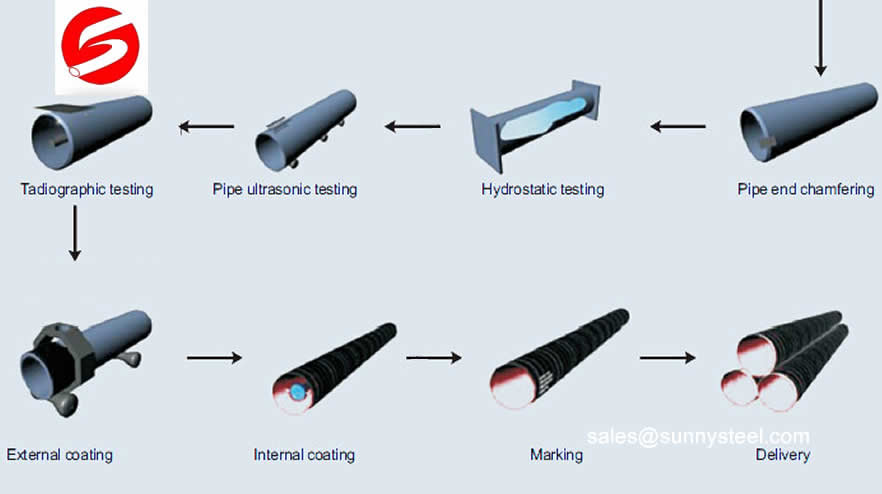

材料重试→真空悬挂→电路板探头→翻转→在Demi Plate(J成型)上的卷曲→平面卷曲在板边缘→松开→Enter Demi钢板(C成型)Demi钢板→卷曲→松散→弯曲→预焊→焊接引用(淬火)弧板→焊接→清点焊接→机械修复端引用静水压试验(放出)电弧板→超声波检查→机械膨胀→管末端超声波检测环的分层测试将ut→x-Ray检查→磁性粒子检查成品检测→称重和测量长度→外防腐→内部腐蚀→标记→交付。

焊接钢管(用焊接制造的钢管)是由平板制成的管状产品,称为Skelp,形成,弯曲并为焊接制备。

Our team is highly trained and experienced in servicing and producing all types of steel supplies.