ASTM A335 P22 elbow is produced by ASTM A335 standard, used to be installed between two lengths of pipe or tube allowing a change of direction.

We supply a full range of ASTM A335 P22 elbow schedules ranging from SCH 5 thru Double Extra Heavy, we deliver ASTM A335 P22 elbow with Exceptional sizes & Quality.

Sunny Steel is the most acclaimed manufacturer, exporter, distributor and supplier of industrial ASTM A335 P22 elbow with required test certificates. You can also Order small quantities, we will be happy to quote best price for small and large quantities & can typically deliver the ASTM A335 P22 elbow in minimum time frame anywhere around the globe.

ASTM A335 P22 elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends. The ends may be machined for butt welding , threaded , or socketed , so the carbon steel elbows are consist of butt weld, thread elbow socket elbow and other series. The material is selected according to the application use such as high temperature use, sanitary fitting, regular industrial use etc.

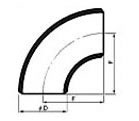

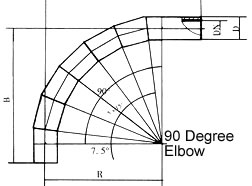

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 180° or 90° angle, though 45° elbows are also made. The ends may be machined for butt welding (SW) or socketed welding(SW) etc.

Most elbows are available in short radius or long radius variants. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

Elbows are categorized based on various design features as below:

材料

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.

SHS-self-propagating ceramic composite steel pipe and fittings, the new generation of wearable and corrosion resistant engineering pipeline, belongs to "863" Hi-tech Plan products.It is the ideal wearable and corrosion resistant engineering pipeline, with wear resistance 15 times higher than common steel pipe, smooth inner surface, and favorable liquor resistance.

Application of pipe elbows:

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc.

ELL & ELLS

There are different varieties of pipe fittings made of various materials and available in various shapes and sizes.

Our team is highly trained and experienced in servicing and producing all types of steel supplies.